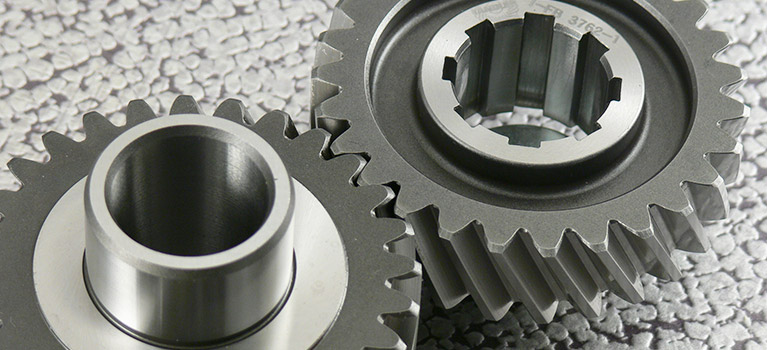

Downstream gear parts often pay the price for significant performance enhancement. This applies particularly to the crown wheel and pinion set on the drive axle. Then there are outside influences that impact noticeably on the gears, for instance if the car jumps when going over a hill and then comes back down again. We frequently encounter customers whose gear sets have broken during this kind of manoeuvre.

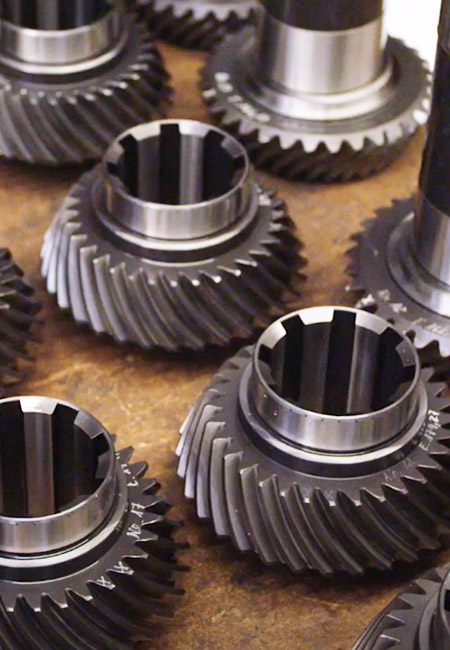

In one specific case, we designed the helical gearing for maximum durability and improved details in the geometry of the pinion. As always, we only used the ideal materials and applied the best possible heat treatment. After all, there’s barely any other factor that is as important for letting the gears run smoothly as surface hardness, combined with excellent core strength. We then treated the surface of the gears with shot peening and blasting to ensure better protection against the formation of stress cracks and to prevent excessive stress.