We offer you:

Advice and service:

- Tell us what you need, we shall listen.

- We will give you tips on how best to complete your project

- You will benefit from our experience with gearing technology

- We shall send you an unbinding quotation at no charge

- And we’ll treat the parts you send us as if they were our own

Designing gears:

- We use the parts you send us to determine the original gearing data

- Our cutting-edge software lets us recreate the gears according to modern standards

- The gears are optimised for smooth running and durability

- We check and calculate your preferred gear ratio/modifications

Preparation of drawings:

- We meticulously measure your sample parts

- You will benefit from the highly precise measurement equipment such as our 3-D measuring machine or the gear measuring machines produced by Klingelnberg, which are installed in air conditioned rooms

- Once the measurements are taken, we use our 3-D CAD system to produce the manufacturing drawings, which we then double check.

Manufacturing:

- we produce everything ourselves in our factory in Bremen, apart from standardised parts such as seals, screws or bearings

- We only use high-quality, gear-optimised materials

- Our manufacturing standards are nothing short of excellent

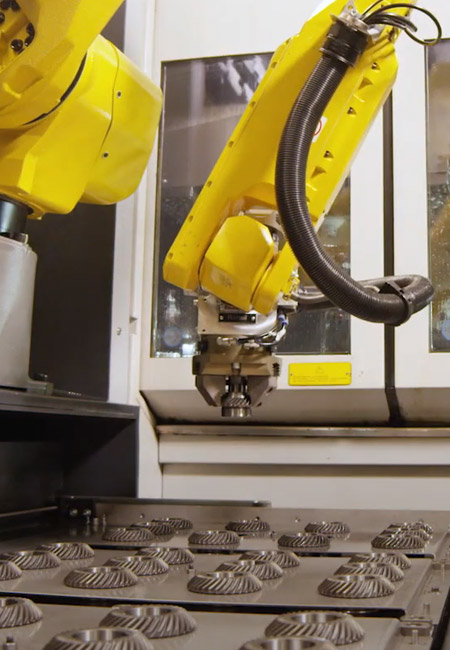

- Our manufacturing systems can accommodate batches of one and are ideal for small production runs

- The production control tool FELIOS ensures stringent adherence to delivery schedules.

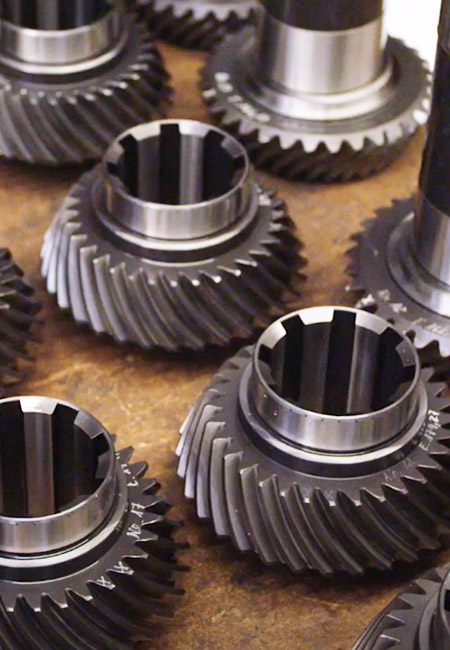

Modern machinery

Our modern machinery is equipped for the following work

- sawing

- milling (5-axes)

- turning (with rotating tools)

- gearing (bevel and spur gears etc.)

- grinding, inside and outside

- profile grinding, inside and outside

- gear grinding (bevel and spur gears etc.)

- levelling

- eroding

- signing

- lapping

Quality management:

- Complete in-process quality control during each stage of work

- Traceability of individual production steps

- Final inspection before shipping

- Precision measurement of the installation dimensions with wear pattern inspection

100% vertical range of manufacture

Heat treatment in our own hardening shops in Bremen and Hamburg:

- Immense experience in the heat treatment of complex gear parts

- We use spectral analysis and hardness measurement technology to determine the precise material composition and state of the sent parts

Practically all heat treatment procedures are possible:

- Case hardening/carburization

- Hardening/tempering

- Gas nitriding

- TAN-Ox

- Soft nitriding (QPQ)

- Vacuum hardening

- Inductive hardening

- Stress relief heat treatment

Your contact Jörg Pohlmann

Telephone

Let us know your wishes. We look forward to hearing from you:

Contact form

Our solutions

We offer you customised solutions based on sample parts or drawings. No matter which vehicle you own: We manufacture high-quality gearing parts for you.

Our production

Around 200 experienced employees, modern machinery and our in-house hardening shops ensure that you get the perfect result from us.

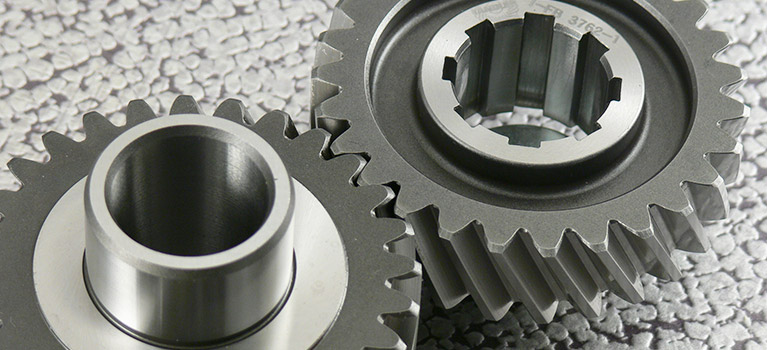

Crown wheel and pinion sets

We manufacture bevel gear sets for drive axles or auxiliary drives according to samples or drawings. We can also realise translation changes according to your wishes.

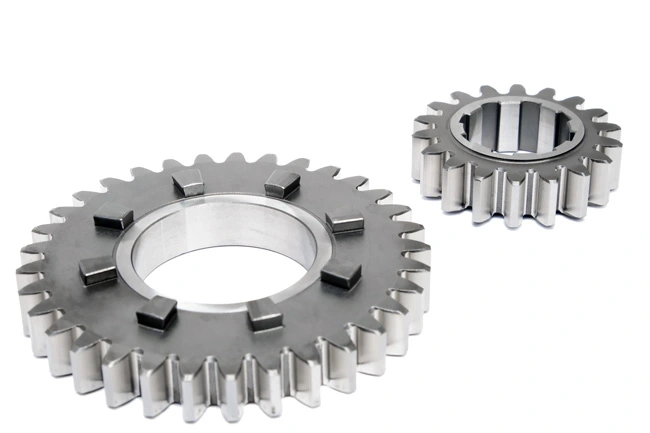

Gear wheels

In the event of damage to the gears of your vehicle, we can in many cases produce new gears to sample, especially if they are racing gears.

Gearing technology for engines

Newly manufactured parts ensure optimum performance again if the original parts are worn or defective, e.g. oil pumps or camshaft drives.

Custom gear parts

No matter which gearing part you need a replacement for, please contact us. In many cases we can help so that you can continue to enjoy your vehicle.